Conveyor Fabrication and Installation

Dependable Design

Conveyor Fabrication and Installation

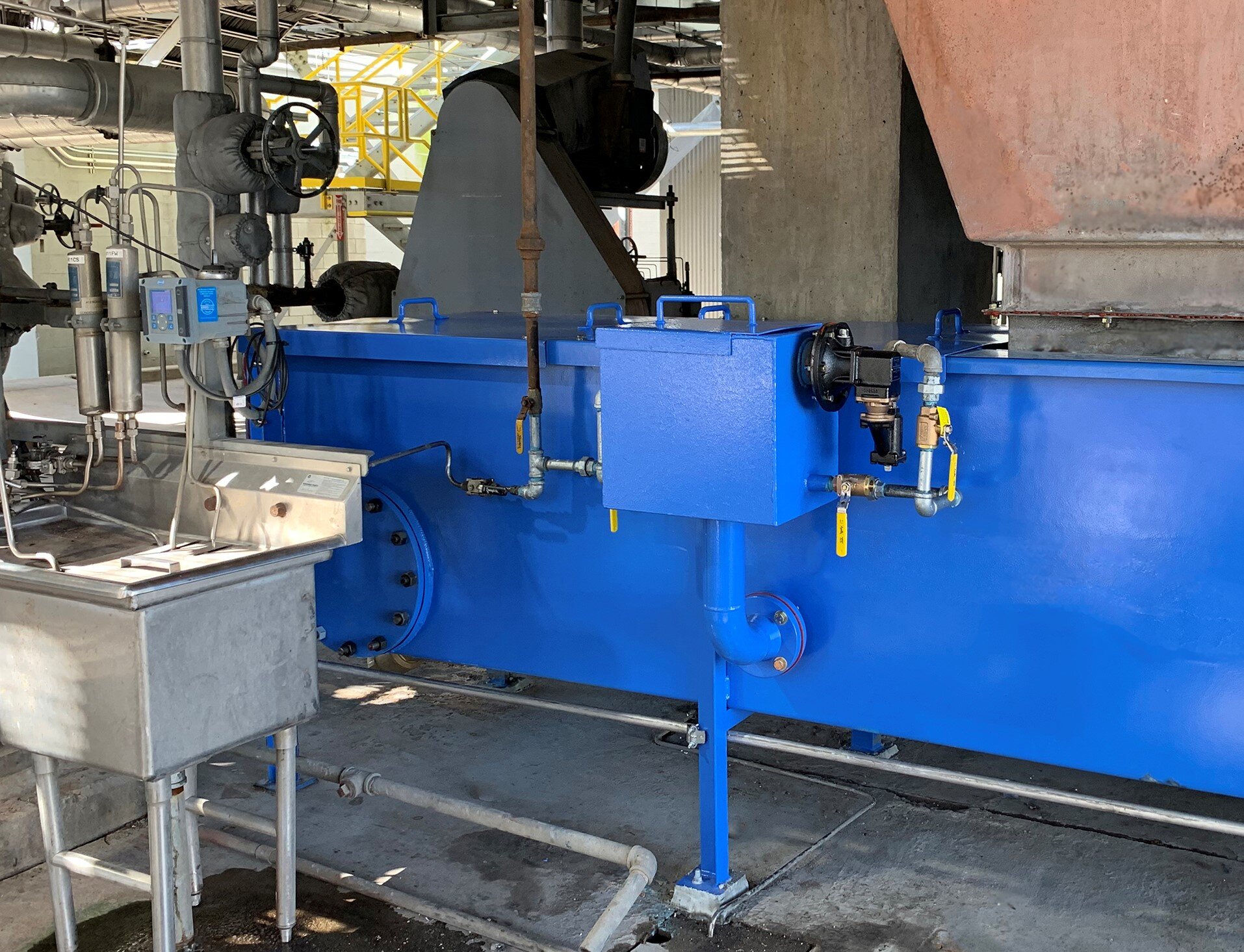

Fabrication | MechanicalBy altering the design of a bottom ash conveyor for a biomass boiler system, we were able to help a customer improve process reliability and lower maintenance expense. The original 2-pass conveyor had been constructed using a traditional abrasion-resistant plate, but excessive wear of the body and chain rails was resulting in damage to the chain and chain drive. Our new, improved design featured fewer moving parts, a direct drive system, a chain that stays lubricated in water, and replaceable UHMW liners throughout.

Close collaboration between our in-house engineering, fabrication, quality control, and mechanical teams brought additional value to the construction and installation phases of the project. We fabricated the new conveyor trough and walls along with water fill boxes and lids, support stands, and base plates, and installed removable UHMW liners. Quality Control inspections and testing were conducted throughout fabrication. Installation of the new conveyor included placing a chute between the existing hopper and the conveyor inlet and completing water piping connections. Our scope finished with startup and commissioning.