Using Piping Isometrics to Improve Fabrication and Construction

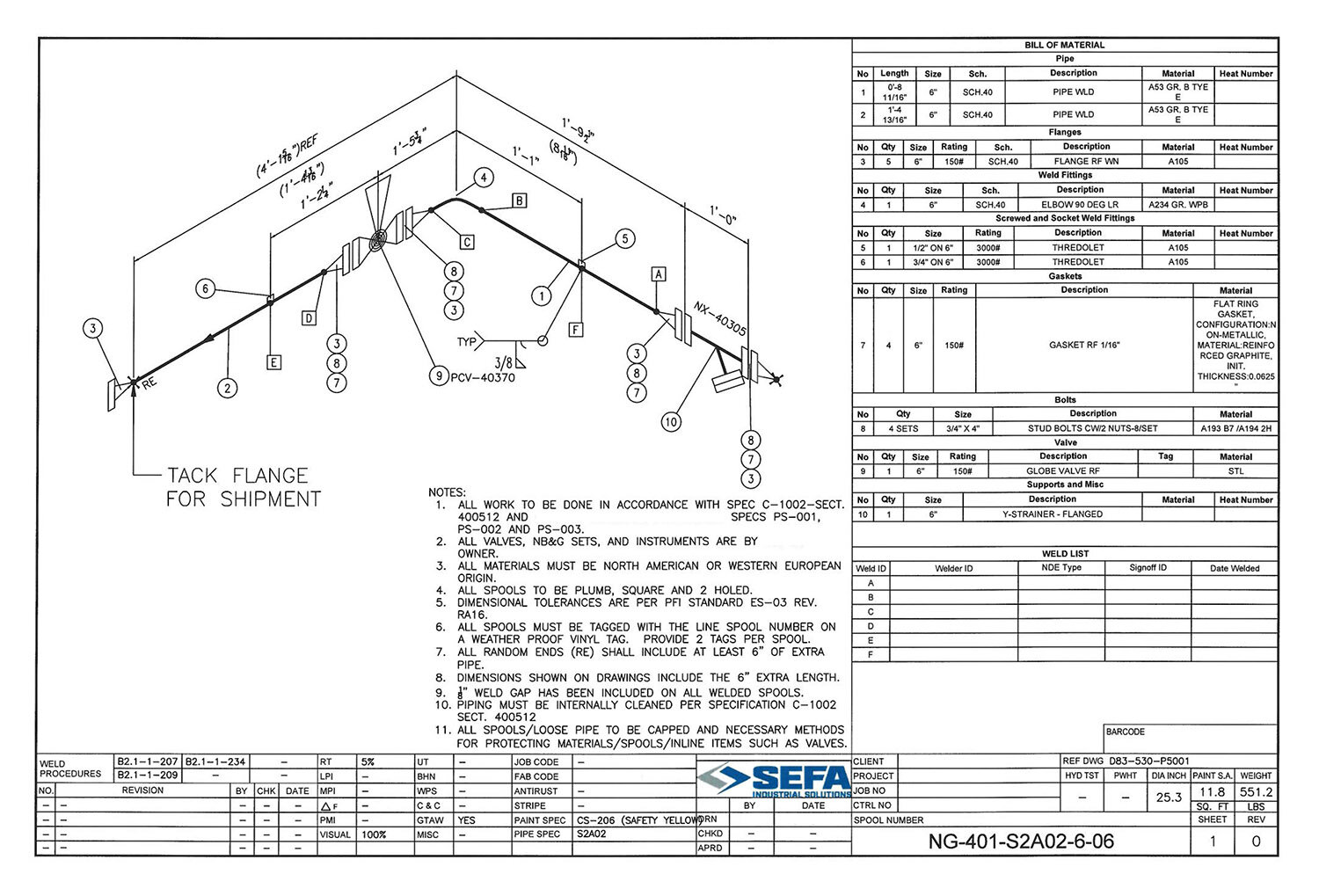

For accurate and quality fabrication of process piping, our team often works with customers to facilitate the development of piping isometrics. Piping isometrics are three-dimensional drawings of pipe spools and can be created from engineering piping and instrumentation diagrams. Piping isometrics include exact pipe dimensions (length, width, height), fitting and valve types and locations, and weld standards. The level of detail is valuable for accurate fabrication, construction, and installation.

Complex piping isometrics may be broken down into smaller, simpler isometrics by a fabrication engineer. Often called “shop drawings,” details and dimensions are transferred to these subsets and double-checked before the drawings are delivered to fabrication or construction teams. For large projects with numerous pipe spools that require high-level organization, components can be gathered and kitted along with the corresponding isometric for later assembly.

Piping isometrics are also a resource for Quality Control. A Quality Control Inspector uses piping isometrics to verify pipe dimensions. For welds, the isometric acts as a “weld map,” documenting the weld procedure and who completed each weld. A Quality Control Inspector can also document weld inspections on the isometric. Project standards may require that a certain number of welds be examined using X-ray. If a weld does not pass X-ray examination, isometrics help the Inspector identify and examine other welds completed by the same person to verify quality.

In addition to providing important specifications, there are additional benefits of piping isometrics:

Allows pipe spools to be fabricated in a controlled environment if required by a project’s quality standards.

Promotes project efficiency since pipe spools can be fabricated at an offsite location and then shipped for installation.

Eliminates construction guesswork when a section of piping later needs to be replaced.

For more information on piping isometrics or on how we might support your next piping project, please contact us.