Quality Control: Verification of Parts and Assemblies

An important part of SEFA’s Quality Control System is our process for verifying parts and assemblies on customer projects. The process is vital to ensure the accuracy of parts and assemblies, which is as much about the paperwork as the parts, both of which are tracked and documented throughout a project to make sure customer designs and specifications match final construction.

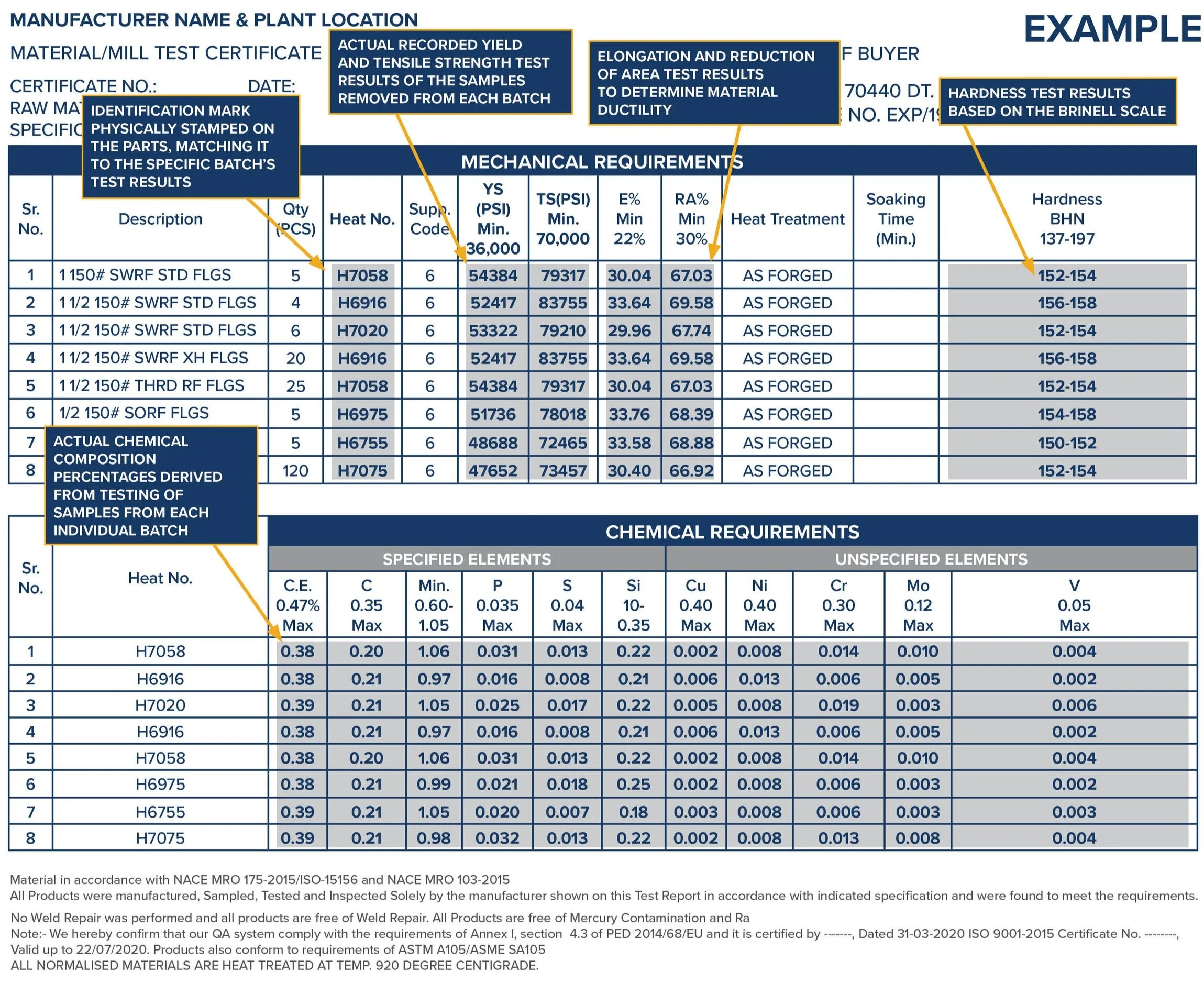

Heat Numbers: Heat numbers are stamped on parts by the manufacturer and help track a group of parts to a specific production batch.

Material Test Report: Sometimes referred to as a mill test report, manufacturers provide a Material Test Report as evidence that parts conform to the required material standard. Quality Control verifies that the heat numbers on parts match the heat numbers on the Material Test Report. Quality Control also reviews the chemical and physical properties listed on the Material Test Report to make sure the parts match the requirements of ASME Section II.

Bill of Materials: Included as part of an engineering design package, a Bill of Materials provides the material standard, dimensional standards, and testing requirements for parts and assemblies. The Bill of Materials is used by the contractor to order the specified parts.

Purchase Order: A Purchase Order documents the contractor’s order. Quality Control verifies that the parts listed on the Purchase Order match the parts on the Bill of Materials. The delivery is also reviewed to make sure all of the requested parts have been received.