Ash Handling System Conversion

SEFA has a long history of experience with ash handling systems and a breadth of skills for installation or conversion of handling systems. We were proud to be selected for a large retrofit fly ash transfer system project for a coal-fired power plant. The main objective of this project was to convert an existing ‘wet’ sluicing system to a dry handling system using a dry flight conveyor, large bore ash piping, and new fly ash processing equipment on the fly ash silos.

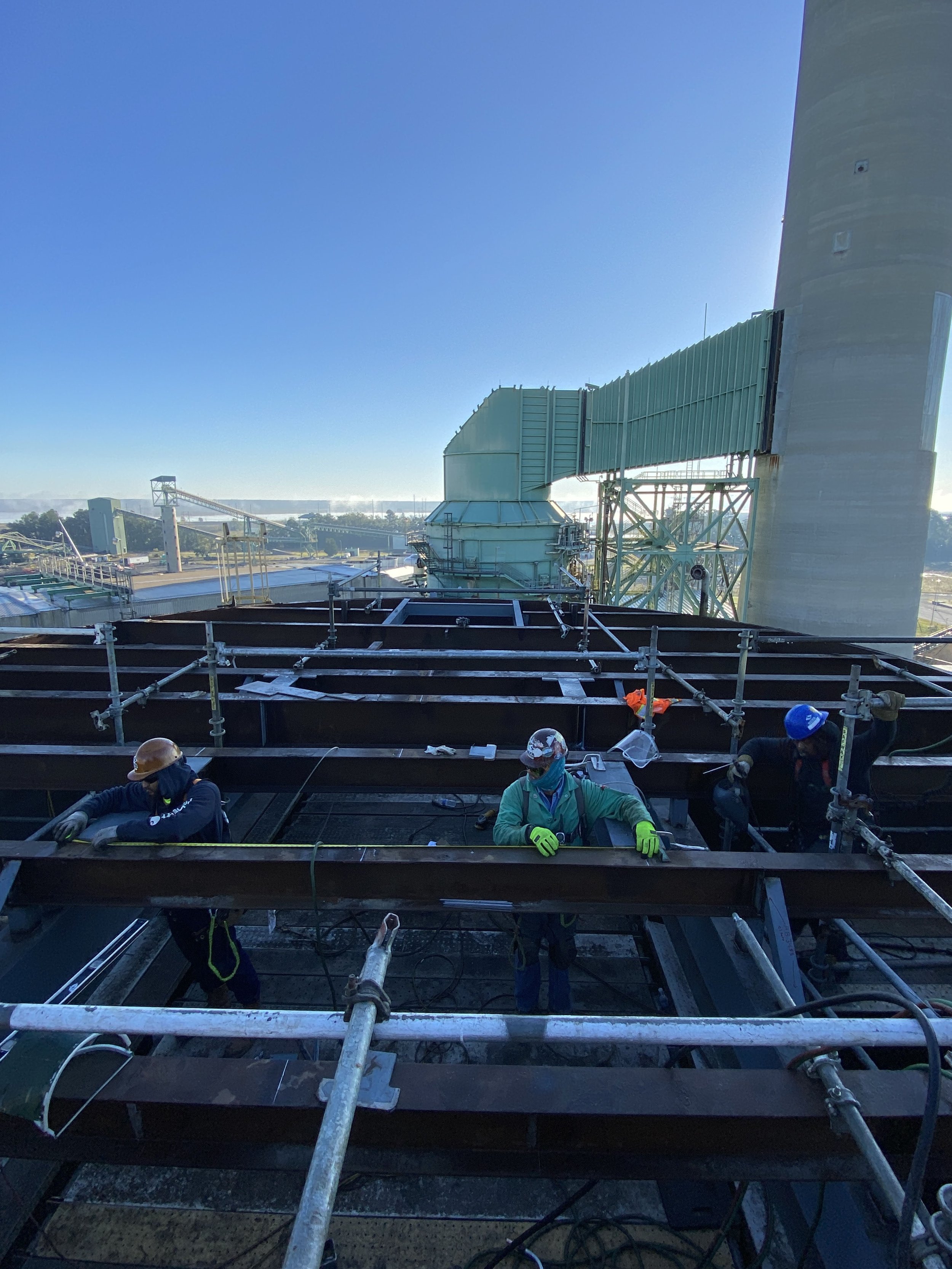

This project highlights our capabilities for Mechanical, Structural Steel, and Electrical, Instrumentation, and Controls services. The scope of the project included mechanical conveying, mechanical piping, structural steel, concrete, and E & IC disciplines. We were involved primarily in the installation phase of this project. Equipment supplied by the client included the filter separators, drag chain conveyor, bin vents, checkered plate, large bore fly ash piping, and variable frequency drives (VFD’s). We installed this equipment and supplied all ‘support’ structural steel for the new equipment, the electrical wiring, and junction boxes.

We completed demolition of the existing ash sluicing system equipment which included ash hoppers, water, and air piping, along with roof top silo equipment such as bin vents and filter separators. Following the demolition and installation of structural support steel, we then installed the ‘fly ash dry handling’ equipment.

This large, multi-disciplined contract was handled and supervised by our own team. The complexity of scope and disciplines for this project required a team approach during the two-month outage, which included structural steel, heavy crane lifts, and mechanical piping, combined with the electrical installation. SEFA organized and successfully completed critical lifts over 22,000 lbs. and over 100’ high utilizing a 250-ton crane.

Up to 40 skilled craftsmen were on-site at the peak of production, including ironworkers, millwrights, pipe fitters, pipe welders, structural welders, electricians, foreman, superintendent, project engineers, project manager, operations manager, and our dedicated Safety Specialist.

The original scope was a two-month outage and was extended as additional services were requested by the client.

Highlights of the project scope included:

Demolition of existing ash sluicing system including process equipment, mechanical piping, and hopper tanks.

Demolition of ash handling equipment on the fly ash silos including mechanical separators, bin vents, roof checkered plate, and misc. structural steel.

Installation of drag chain conveyor below the economizer including air piping.

Installation of structural support steel and access platforms for new drag chain conveyor.

Replacement of silo rooftop equipment including mechanical separators, bin vents, and mechanical ash piping.

Installation of large bore ash convey piping in existing pipe rack structure.

Modification of existing rooftop silo support steel for new ash handling equipment along with the installation of new support steel for this equipment.

Installation of new control panels for ash handling system including VFD control panel and mechanical separator control panel.

Modification to existing control system hardware and installation of new PLC hardware

Installation of plant utility piping including flush water drain piping and instrument air piping for control valves.