Mechanical Installation of an Instrumentation Upgrade

Mechanical Installation of an Instrumentation Upgrade

Pulp & Paper Manufacturer

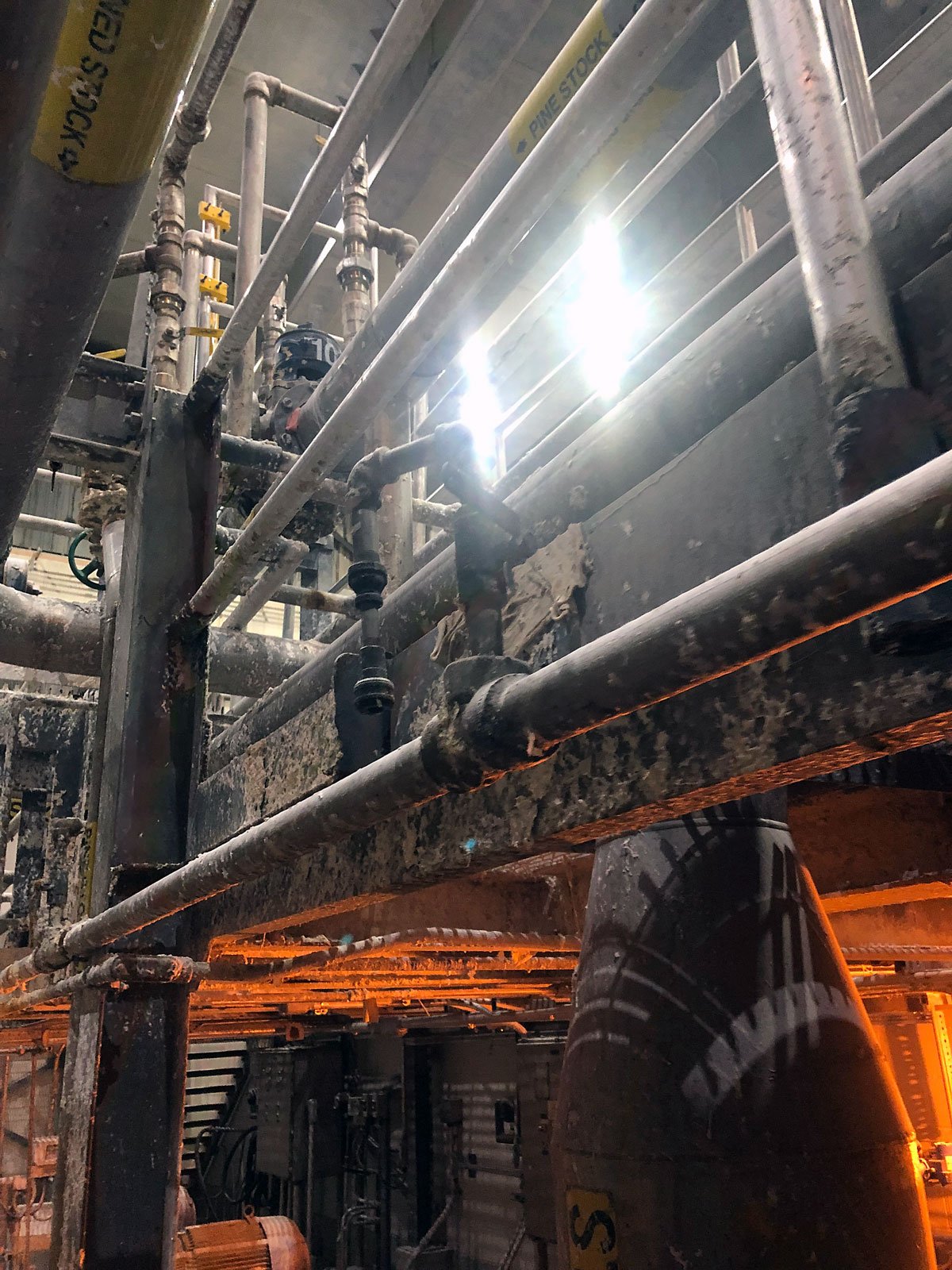

Mechanical | Fabrication | Installation | ModificationsWe recently completed the mechanical installation of an instrumentation upgrade project for a major paper manufacturer.

The one-year project included mechanical installation for an instrumentation upgrade on two paper machines, including piping fabrication and installation, support fabrication and installation, miscellaneous steel fabrication and installation, equipment installation, laboratory upgrades, and machine modifications.

Scope of work:

Install 61 in-line pulp analyzers including PDVF sample tubing back to the laboratory.

Perform 100+ tie-ins to existing systems.

Install approximately 8000 feet of stainless-steel, small-bore piping (air and water).

Installation of the water-cooling system including foundations, pumps, heat exchangers, tanks, and associated piping.

Remodeling of the wet end laboratory including building upgrades, equipment, and piping installation.

Installation of paper quality analyzers including associated utilities and machine upgrades.

Installation of wet-end analysis equipment including sample and utility piping.

Demolition of an existing manlift.

Fabrication and installation of a new pulp mixing header system, including 500’ of 18” piping.

Relocation of an existing 300hp pump.

Work was accomplished based on a variety of schedule requirements. This included on-the-run work, short-duration (1 day) maintenance outages, and long-duration mill outages. Work was completed on time and within budget. SEFA successfully managed multiple work scopes, manpower requirements and schedules. The project was completed with 0 recordable safety incidents.