Integrated Equipment Installation

Integrated Equipment & Electrical Installation

New Installation and Capital Improvements

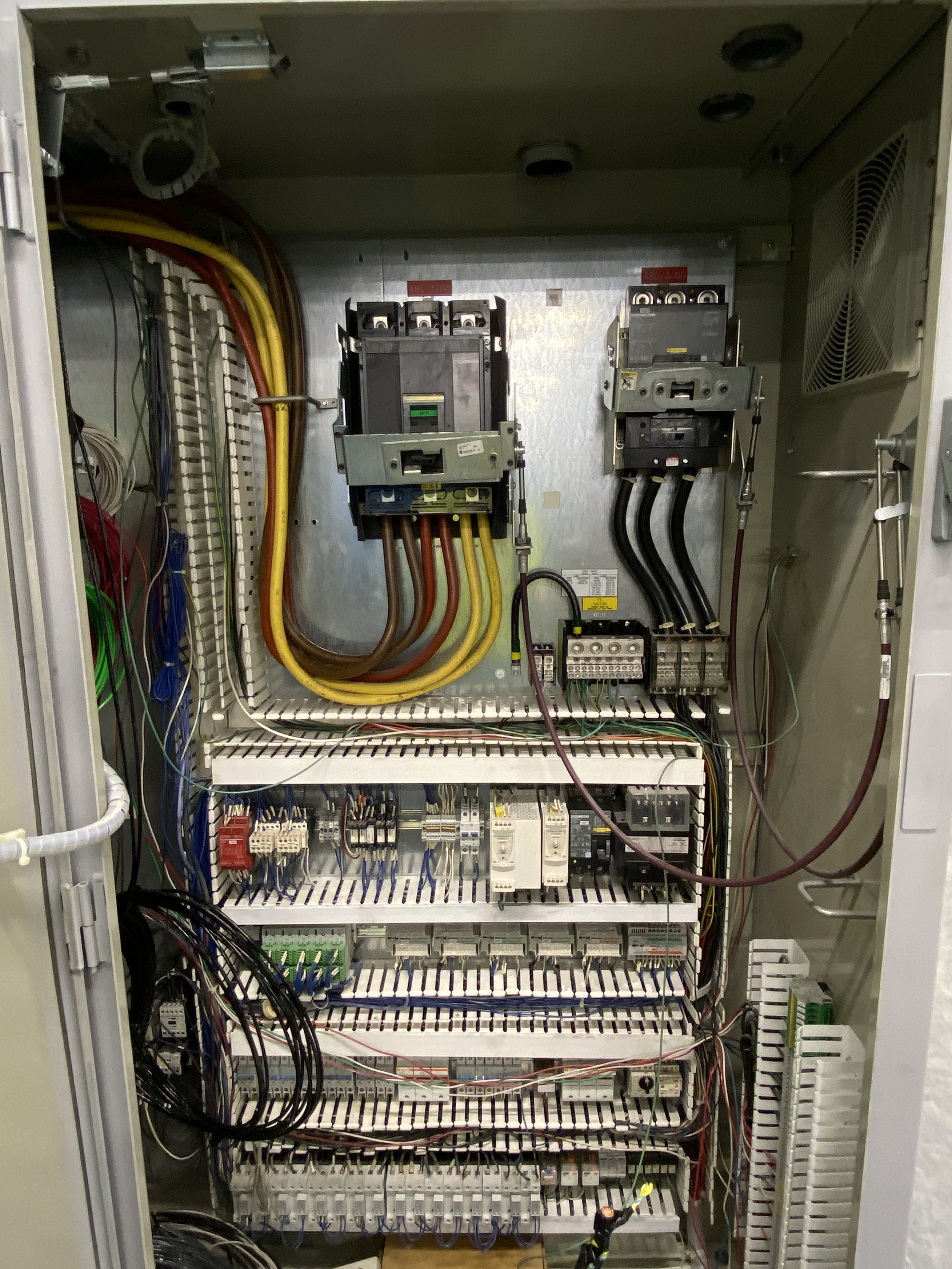

Mechanical | Electrical | Instrumentation & Controls | FabricationOur multi-craft Journeymen supported the installation of three plastics manufacturing machines of varying size screws and dies used for the extrusion process. We fabricated material handling equipment and were responsible for the electrical installation, including feeder, cabling, rewiring, and PLC work.

Scope of work:

Installation of chilled water service with plant air drops

Fabrication of stainless-steel boxes, chutes, and collars for conveying equipment

Installation of stainless-steel exhaust headers and drops for the vacuum pump system

Installation of hoppers, feeders, and mixers

Installation of new support beams and checkered plate floor

Electrical installation of new feeder cabling for 600-amp and 250-amp breaker

Local control panel re-wiring and PLC work (with the relocation of the HMI panel)

Installation of machine instruments, motor starters, and motors

Electrical installation of a 4.5 single screw extruder