Ash Handling System Conversion

Ash Handling System Conversion

Mechanical/Structural Installation of Ash Processing Equipment for a Coal-Fired Power Plant

Mechanical | Structural Steel | Electrical | Instrumentation & ControlsThe main objective was to convert an existing ‘wet’ sluicing system to a dry handling system using a dry flight conveyor, large bore ash piping, and new fly ash processing equipment.

The scope of the project included mechanical conveying, mechanical piping, structural steel, concrete, and E & IC disciplines, such as installation of:

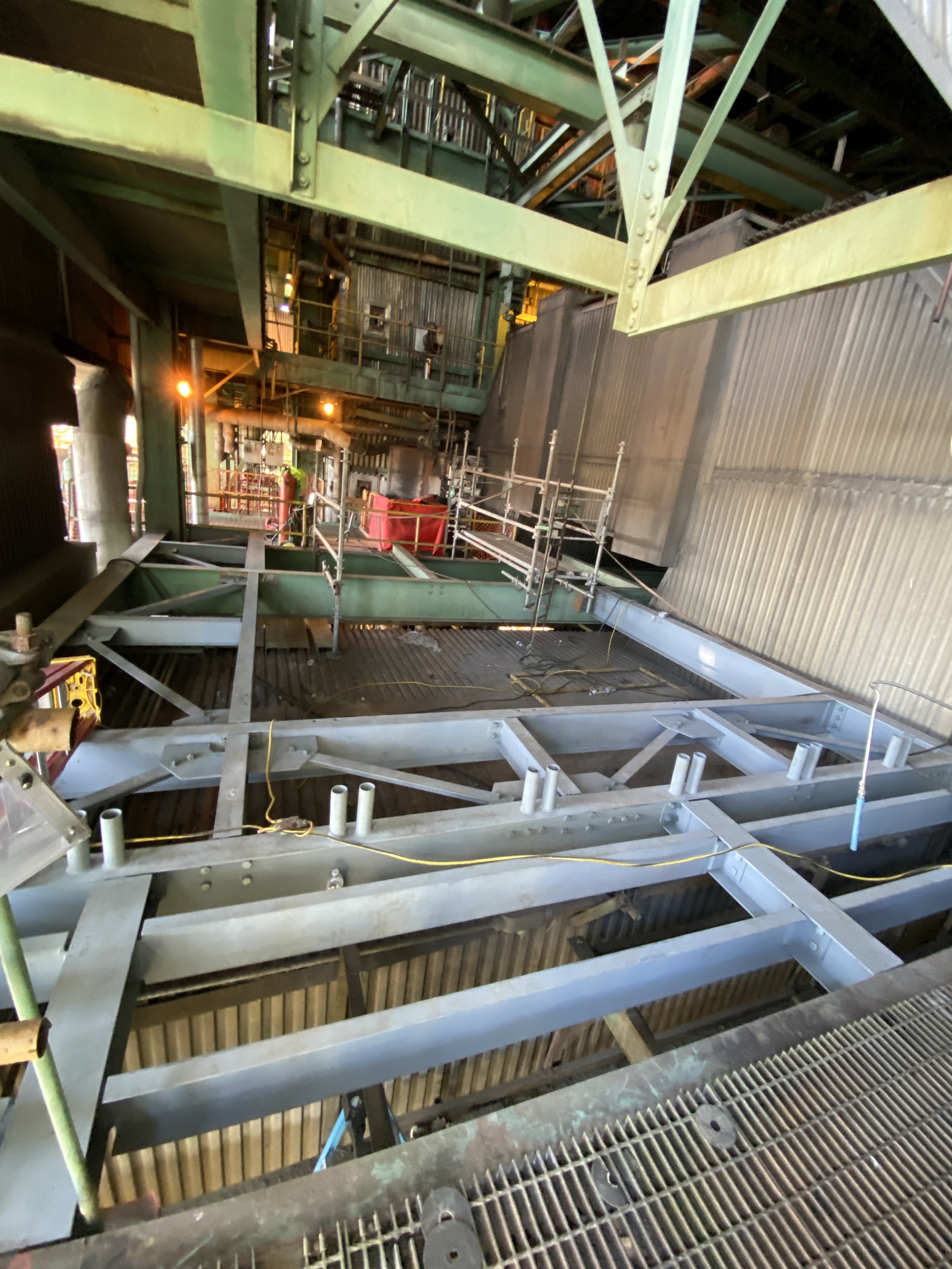

Drag chain conveyor below the economizer including air piping

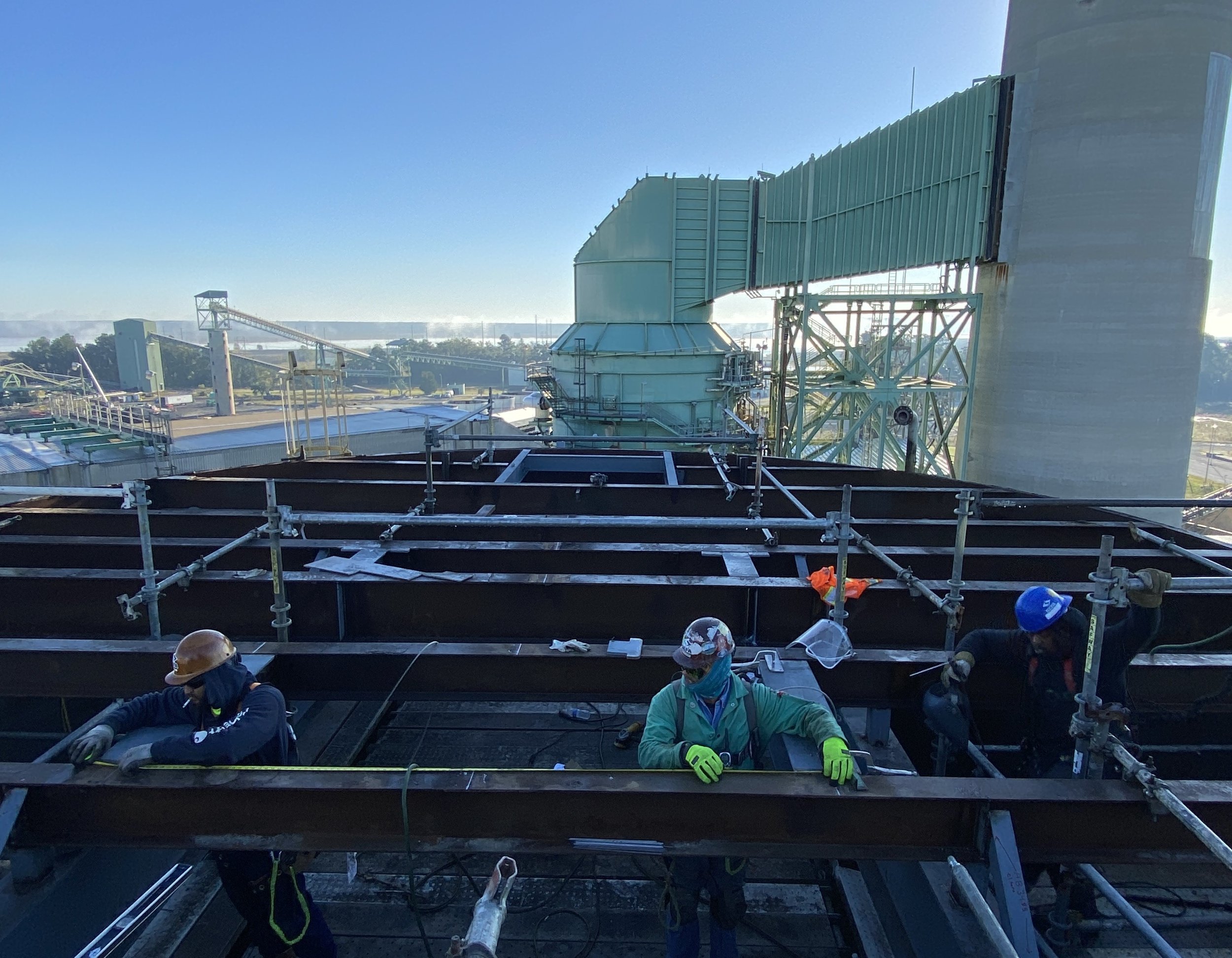

Structural support steel and access platforms for new drag chain conveyor

Large bore ash convey piping in existing pipe rack structure

New control panels for ash handling system including VFD control panel and mechanical separator control panel

New PLC hardware and modifications to existing control system hardware

Interior work was completed in phases during manufacturing down days.

SEFA organized and successfully completed critical lifts over 22,000 lbs. and over 100’ high utilizing a 250-ton crane.